5 important factors worth considering when looking for the best mill drill machine

When deciding to invest in a mill drill machine, it’s important to look closely at all the important factors. This decision can make a big difference in how well your machining tools work and how productive you can be. The power, precision, versatility, and durability of the machine all play a role in finding the right fit for your workshop. By exploring and understanding these important factors, you can make a smart choice that matches your machining needs and goals for the future.

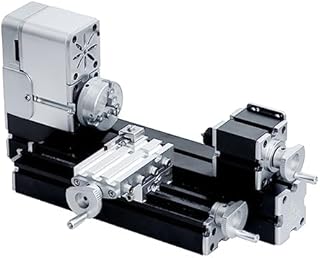

See our guide to the best mill drill machine.

Power and torque

When people buy a mill drill machine, they often think about how powerful it is, as well as how much torque it has. While it may be tempting to focus only on horsepower, ignoring the importance of torque can cause missed opportunities. Power, which is usually measured in watts or horsepower, shows how well the machine can do different tasks. But torque, which is the force that makes the machine work on tough materials, is just as important. The balance between power and torque is what makes drilling and milling efficient, turning raw energy into precision.

Choosing a mill drill machine with the right power-to-torque ratio can make you more productive and allow you to work on a wider range of projects. If you get too much power without enough torque, you might have problems and not be able to do as many things. On the other hand, a machine with the right amount of torque can handle tough materials and complex designs easily, showing that it’s versatile and reliable. By understanding how power and torque work together, buyers can make smart choices that match their needs and goals. Having a good balance of power and torque is key to getting the most out of a mill drill machine, opening up new possibilities in precision machining for users.

Table size and travel

When you’re looking to buy a mill drill machine, one key factor to consider is the size of the table and how it affects the machine’s capabilities. The table size is important because it determines the size of the materials you can work with and how versatile the machine is. A larger table gives you more space to maneuver and position your workpieces, which allows for more precise and flexible machining. It also provides plenty of room to securely clamp different workpieces in place, ensuring stability and accuracy during milling and drilling.

Furthermore, the size of the table affects how far the machine can move along the X and Y axes. A larger table means you can work on bigger projects more easily. This extended range of movement allows you to tackle intricate designs and work with large materials without any limitations. Buying a mill drill machine with a substantial table size not only improves workflow efficiency but also expands the possibilities of what you can accomplish in a workshop. It’s a valuable tool for both hobbyists and professionals in the machining industry.

Spindle speed

When choosing a mill drill machine, one important factor to consider is the spindle speed. The spindle speed plays a key role in how well your milling and drilling work turns out. Higher spindle speeds can lead to more accurate and smoother finishes on your projects, especially for intricate designs. Having a machine with variable speed settings allows you to work with a variety of materials and applications easily. Investing in a mill drill machine with the right spindle speed capabilities is an investment in the quality of your work and how efficiently you can get things done.

The spindle speed also affects how well your machining processes perform. If a machine has a low spindle speed, it can result in poor results, wasted material, and longer production times. Choosing a mill drill machine with a strong and adjustable spindle speed can help make your operations smoother, increase your output, and improve overall performance. In machining, precision and speed are essential for success, so don’t overlook the importance of spindle speed when selecting a machine. It can make a big difference in how well your projects turn out and how creative you can be.

Construction and build quality

When buying a mill drill machine, it’s important to think about how it’s built. Getting a machine made with strong materials is crucial. It will last longer and work better. Machines with high-quality construction are tough and can handle tough jobs like milling and drilling without breaking down. A well-built mill drill machine stays stable and doesn’t vibrate much, so you get accurate and consistent results.

A good build quality also makes using the machine easier and safer. It’s simpler to operate, adjust, and has safety features. Choosing a mill drill machine with great construction means you’ll have a reliable tool that works well for a long time. Whether you’re a professional doing machining work or just a hobbyist, a well-constructed machine is key for it to work properly. Investing in a mill drill machine with top-notch build quality guarantees precision, durability, and satisfaction in the long term.

Price and budget constraints

When you’re looking to buy a mill drill machine, figuring out the right price can be tough. You have to balance quality with affordability, which is really important. While going for a cheaper machine might save you money at first, it could end up costing you more in the long run if it keeps breaking down. You need to find a good balance between how much you spend upfront and how well the machine will work in the long term to make sure you have a smooth and efficient experience.

It’s not just about how much money you have when you’re choosing a mill drill machine. You need to do your homework, look at different options, and pick the features that fit your needs the best. Even though it might be tempting to go with the cheapest option, you have to think about how well the machine can do its job, how accurate it is, and how reliable it is to avoid problems later on. By thinking about both the cost and the benefits of a mill drill machine, you can make a smart choice that helps you work better and faster without sacrificing quality. Remember, investing in a good machine now can set you up for success in the future.

Conclusion

Mill drill machines are versatile and efficient tools that represent precision and functionality in the machining industry. They can perform both milling and drilling operations and have a compact design suitable for different workshops. These machines are essential for craftsmen and hobbyists as they provide a reliable way to bring intricate designs to life. By utilizing mill drill machines, we can unlock endless possibilities for creativity and precision engineering, enhancing the quality of our creations. Want more info on shower shoes, check the best shower shoes.